AI in supply chain helps businesses boost efficiency fast by improving demand forecasting, automating repetitive tasks, optimizing logistics routes, reducing delays, cutting operational costs, and enabling real-time visibility across every step of the supply chain. Companies can make smarter decisions in minutes instead of hours, respond quickly to changing market conditions, and ensure products move smoothly from manufacturing to delivery with fewer errors and lower costs.

Why AI Is Becoming Essential for Supply Chains

Supply chains have become more complex than ever. Customers expect next-day delivery, global disruptions are unpredictable, and demand patterns change rapidly. Traditional supply chain systems often fail to keep up because they rely heavily on manual decisions, limited forecasting tools, and siloed data.

Artificial Intelligence (AI) changes this reality completely.

AI connects data, predicts risks, improves planning, and automates workflows — all in real time. From warehouse operations to transportation planning, AI dramatically improves accuracy and speed. This is why leading brands like Amazon, Walmart, DHL, Maersk, and Tesla have already embraced AI-driven supply chain models.

In this article, you’ll discover how AI works in the supply chain, what benefits it delivers, where it fits into daily operations, and how businesses of any size can implement it effectively.

What Is AI in Supply Chain?

AI in supply chain refers to the use of artificial intelligence technologies — including machine learning, predictive analytics, robotics, and automation — to improve how products are planned, produced, stored, and delivered.

AI analyzes large amounts of data from different sources, predicts outcomes, and recommends or automates decisions such as:

- How much stock to order

- Which routes reduce delivery delays

- When a machine will break down

- How to reduce excess inventory

- Where disruptions might occur

- What demand will look like in the next week, month, or quarter

AI brings speed, intelligence, and automation to every part of the supply chain.

Why AI in Supply Chain Matters Today

Modern supply chains are far more complicated than they once were. Companies now manage a wide network of suppliers, operate across multiple countries, and rely on global transportation routes that are constantly shifting. The traditional way of running supply chains — with spreadsheets, manual decisions, and outdated forecasting tools — can no longer keep up with today’s pace.

Supply chains today face challenges such as:

- Multiple suppliers that vary in reliability, lead times, and prices

- Global warehouses that demand real-time visibility and coordination

- Rapidly fluctuating customer demand, driven by trends, seasons, and unpredictable events

- Transportation constraints, including limited capacity, traffic delays, and strict delivery windows

- Rising fuel and operational costs that directly impact shipping and logistics

- Uncertain global markets, influenced by political shifts, weather events, and economic instability

AI helps businesses handle these challenges with speed and precision that human-driven systems simply cannot match.

The real power of AI? It removes the guesswork.

Instead of relying on manual judgment or reacting only after problems occur, AI analyzes data continuously to reveal patterns, predict outcomes, and identify risks early.

This means companies can:

- Anticipate delays before they disrupt operations

- Adjust inventory levels before stockouts or overstocking happens

- Optimize transportation routes ahead of time

- Respond to demand changes quickly and accurately

- Prevent costly mistakes and inefficiencies

AI turns the supply chain from a reactive system into a proactive, predictive engine — ensuring businesses stay efficient, competitive, and resilient in a fast-changing world.

How AI Boosts Supply Chain Efficiency Quickly

AI is transforming supply chains faster than most businesses expect. In many cases, companies start seeing improvements within just a few weeks. By analyzing data, automating manual work, and predicting problems early, AI makes supply chains faster, smarter, and more cost-efficient. Below are the most impactful ways AI delivers quick and measurable results.

1. AI Improves Demand Forecasting Accuracy

Predicting customer demand is one of the hardest challenges in supply chain management. Traditional forecasting often relies on spreadsheets or outdated tools, which leads to guesswork and inaccurate planning.

AI changes this completely by analyzing large amounts of data at once, including:

- Historical sales

- Seasonal patterns

- Current market trends

- Weather changes

- Social media discussions

- Economic signals

With this information, AI creates far more accurate forecasts and helps businesses stay prepared.

Key Benefits

- Reduces overstocking

- Prevents costly stockouts

- Lowers inventory carrying costs

- Helps plan production more efficiently

Better forecasting leads to smoother operations and a more reliable supply chain.

2. AI Enhances Inventory Management

Inventory can make or break supply chain performance. Too much stock wastes money, while too little stock leads to lost sales. AI helps companies find the perfect balance.

AI-powered systems help businesses:

- Identify slow-moving or dead inventory

- Set smarter reorder points

- Predict ideal safety stock levels

- Reduce excess and outdated products

- Improve warehouse space utilization

AI can even place purchase orders automatically when stock levels drop, ensuring nothing runs out unexpectedly.

Result

- Lower costs

- Faster product availability

- Less manual monitoring

3. AI Optimizes Logistics and Delivery Routes

Transportation is one of the biggest expenses in the supply chain. AI route optimization helps companies deliver goods faster while reducing fuel consumption and costs.

AI considers factors such as:

- Weather conditions

- Traffic patterns

- Fuel usage

- Delivery deadlines

- Vehicle load capacity

- Total distance and time

This allows drivers to take the most efficient routes instantly.

Real-World Impact

- Saves 20–30% in transportation costs

- Makes delivery times more predictable

- Increases customer satisfaction and trust

4. AI Automates Warehouse Operations

Warehouses are the heart of supply chains, but they are also one of the most labor-intensive areas. AI helps automate many tasks that were previously done manually.

AI-driven warehouses use:

- Smart robots for picking and sorting

- Automated scanning systems

- Intelligent shelf management tools

- Predictive maintenance alerts for equipment

- Real-time tracking systems

These technologies help workers complete tasks faster and with fewer mistakes.

Immediate Benefits

- Reduced manual errors

- Faster order fulfillment

- Lower operational and labor costs

5. AI Strengthens Supplier Management

Suppliers play a major role in supply chain success. A single delay or quality issue can affect the entire chain. AI helps companies stay ahead by evaluating supplier performance continuously.

AI assesses suppliers based on:

- Delivery performance

- Product quality

- Cost changes

- Past reliability

- Financial health

It can even alert businesses if a supplier is at risk of delays or failure.

This Helps Companies:

- Choose stronger, more reliable suppliers

- Reduce disruptions before they occur

- Negotiate better deals with confidence

6. AI Detects and Prevents Supply Chain Risks

Supply chains face many threats — from natural disasters to political issues to unexpected changes in demand. AI acts like a real-time risk prediction system that constantly watches for warning signs.

AI can detect risks such as:

- Sudden demand spikes

- Supplier delays

- Equipment breakdowns

- Transportation issues

- Compliance failures

- Global news that may affect operations

How AI Reduces Losses

- Predicts low inventory early

- Flags shipments that may be delayed

- Detects fraud or unusual transactions

- Warns about possible quality issues

- Provides actionable alerts for quick decisions

AI helps businesses avoid problems instead of reacting after damage is done.

7. AI Enables Real-Time Visibility Across the Entire Supply Chain

Traditional supply chains often work in fragments — manufacturing, warehousing, logistics, and suppliers operate separately. AI unifies all these parts into one connected system.

AI integrates data from:

- Manufacturing units

- Transportation fleets

- Warehouses

- Retailers

- Supplier networks

This creates a single real-time dashboard that shows every movement happening in the supply chain.

Businesses Gain:

- Instant updates on product location

- End-to-end tracking from production to delivery

- Real-time inventory levels

- Faster order updates

- More confident decision-making

Real-World Use Cases of AI in Supply Chain

1. Maersk – Predictive Logistics and Global Visibility

- What they do: Maersk applies AI to predict shipping delays, optimize routing, and reduce container idle time, turning noisy global data into actionable logistics decisions.

- Why it matters: Predictive models help Maersk cut wasted transit time and improve on‑time performance across ocean and inland legs, which directly lowers costs and improves customer reliability.

- How it works in practice: AI ingests vessel positions, port congestion, weather, and customs data to forecast delays and recommend reroutes or schedule adjustments.

- Tip for others: Start by integrating a single lane or trade route into a predictive model, measure delay reduction, then expand to more routes.

2. Tesla – Forecasting and End‑to‑End Automation

- What they do: Tesla uses AI across production planning and logistics to forecast parts needs, align assembly schedules, and streamline inbound/outbound flows.

- Why it matters: For a manufacturer with complex, tightly coupled production lines, AI reduces bottlenecks and shortens lead times by anticipating demand for components and adjusting procurement dynamically.

- How it works in practice: Machine learning models combine historical production data, supplier lead times, and real‑time factory telemetry to trigger procurement and adjust production pacing.

- Tip for others: Focus AI first on the most constrained workstations or critical components—improving one choke point often yields outsized throughput gains.

3. Walmart – Granular Demand Forecasting and Inventory Health

- What they do: Walmart’s machine‑learning platform analyzes sales history, local events, weather, and search trends to forecast demand at store and SKU level, enabling smarter restocking and fewer markdowns.

- Why it matters: Granular forecasts reduce both stockouts and excess inventory, improving customer satisfaction while freeing working capital.

- How it works in practice: Models run daily (or hourly for fast movers), feeding automated replenishment rules and alerting planners when anomalies appear.

- Tip for others: Combine internal POS data with a few external signals (weather, holidays) to quickly lift forecast accuracy without a full data overhaul.

4. Amazon – Automated Warehousing and Collaborative Robotics

- What they do: Amazon deploys AI‑driven robots for sorting, picking, packing, and autonomous transport inside fulfillment centers, pairing machines with human workers to speed throughput and reduce errors.

- Why it matters: Robotics plus AI increases fulfillment speed during peaks and improves safety and consistency across millions of orders.

- How it works in practice: AI coordinates fleets of mobile robots and robotic arms, optimizes travel paths, and assigns tasks to human‑robot teams for maximum efficiency.

- Tip for others: Pilot robotics in a single fulfillment zone (e.g., high‑velocity SKUs) and measure cycle‑time and error‑rate improvements before wider rollout.

Steps Businesses Can Take to Implement AI Quickly

Implementing AI doesn’t have to be expensive, slow, or disruptive. With a focused plan, clear metrics, and the right mix of tools and people, companies can deliver measurable supply chain improvements in weeks or months rather than years. Below is a practical, step‑by‑step roadmap that turns ambition into action and helps teams move from pilot to scale with confidence.

Step 1: Identify the Biggest Bottlenecks

Start by finding the one or two problems that, if fixed, will deliver the largest and fastest impact.

How to spot the right bottlenecks

- Look at the numbers: review lead times, stockout rates, carrying costs, on‑time delivery, and order cycle times. The largest gaps usually point to the best opportunities.

- Talk to operations: frontline staff and planners will tell you where delays, rework, and manual work concentrate. Their insights often reveal quick wins that data alone misses.

- Prioritize impact and feasibility: choose problems that are high impact but technically feasible with existing data and modest integration effort.

Common high‑impact targets

- Excess inventory that ties up cash and hides demand signals.

- Slow delivery caused by poor routing, manual scheduling, or lack of visibility.

- High logistics costs from inefficient consolidation, empty miles, or poor carrier selection.

- Frequent stockouts that damage service levels and customer trust.

- Poor visibility across suppliers, shipments, and warehouses that prevents fast corrective action.

Practical tip Pick 1–2 areas to start. Narrow focus speeds results and builds credibility for broader change.

Step 2: Collect and Integrate Your Data

AI needs connected, reliable data to produce useful recommendations. You don’t need perfect data to begin, but you do need the right sources and a plan to clean and connect them.

Essential datasets to gather

- Sales and point of sale for demand signals and seasonality.

- Inventory records by SKU and location for stock health and turnover.

- Warehouse operations such as receiving, picking, and cycle counts.

- Fleet and transportation telemetry, route logs, and carrier performance.

- Supplier portals and purchase orders for lead times and delivery reliability.

- ERP and order management for master data, product hierarchies, and financial context.

How to integrate without a full IT overhaul

- Start small: extract a few core tables or CSV exports rather than trying to connect every system at once.

- Use middleware or connectors: many SaaS AI tools offer prebuilt connectors to common ERPs and TMS systems.

- Create a single source of truth for the pilot: a cleaned dataset that the AI model will use. This reduces noise and speeds experimentation.

- Document data assumptions so model outputs can be interpreted and trusted by users.

Practical tip If you’re a small business, begin with sales, inventory, and basic delivery logs. Those three sources alone unlock forecasting and simple route optimization.

Step 3: Use Pre‑Built AI Tools Before Building Custom Ones

Buying or subscribing to proven AI tools lets you move fast and avoid the long lead times of custom development.

Why prebuilt tools are smart first steps

- Lower cost and faster time to value because the heavy lifting of model training and integration is already done.

- Proven best practices baked into the product from other deployments.

- Modular adoption so you can test one capability without changing your entire stack.

Types of prebuilt tools to consider

- AI forecasting platforms that improve demand accuracy and feed automated replenishment.

- Route optimization and dynamic dispatch tools that reduce miles and delivery time.

- Inventory prediction software that recommends safety stock and reorder points by SKU and location.

- Robotic process automation and warehouse robotics for repetitive tasks like sorting and packing.

- Supplier risk monitoring tools that surface delays and alternative sourcing options.

How to choose the right vendor

- Look for quick pilots: vendors that offer 30–90 day pilots with measurable KPIs are preferable.

- Check integration options: ensure the tool can connect to your ERP, WMS, or spreadsheets.

- Ask about explainability: choose tools that show why a recommendation was made so users can trust and act on it.

Practical tip Run a short pilot with a prebuilt tool on a single product family or route. Measure results, then decide whether to extend, replace, or build custom features.

Step 4: Train Your Team

Technology alone won’t change outcomes. People must understand, trust, and use AI outputs in daily decisions.

Who to train and what to teach

- Planners and buyers on how to read AI forecasts and adjust safety stock.

- Warehouse supervisors on new workflows, robot interactions, and exception handling.

- Logistics coordinators on route recommendations and dynamic dispatch tools.

- IT and data teams on data pipelines, monitoring, and model retraining schedules.

- Leadership on KPIs, governance, and how to interpret ROI.

Training best practices

- Hands‑on sessions where users work with real cases and see immediate benefits.

- Shadowing and pairing where AI recommendations are reviewed alongside human decisions until trust builds.

- Clear escalation paths for exceptions so users know when to override AI and how to feed corrections back into the system.

- Short, focused documentation and quick reference guides rather than long manuals.

Practical tip Celebrate early wins publicly. When a planner sees fewer stockouts or a driver saves time, share the story to build momentum.

Step 5: Scale AI Across the Supply Chain

Once pilots prove value, expand methodically to capture larger ROI while managing risk.

A sensible scaling sequence

- Expand horizontally: apply the successful model to more SKUs, stores, or lanes.

- Expand vertically: add complementary capabilities such as predictive maintenance or supplier intelligence.

- Automate closed loops: move from recommendations to automated actions where safe, such as auto‑replenishment for low‑risk SKUs.

- Standardize governance: define model ownership, retraining cadence, and performance monitoring.

Areas to scale into

- Warehouse robotics for high‑volume fulfillment zones.

- Supplier intelligence to proactively manage risk and diversify sourcing.

- Predictive maintenance to reduce equipment downtime and unplanned stoppages.

- Automated scheduling and workforce planning to match labor to demand dynamically.

Measuring success at scale

- Track leading indicators such as forecast accuracy, order cycle time, and on‑time delivery.

- Monitor financial metrics like inventory turns, carrying cost reduction, and transportation spend.

- Measure adoption: percentage of decisions influenced by AI and user override rates.

Practical tip Keep scaling in waves. Each wave should have a clear owner, KPI, and a short feedback loop to refine models and processes.

Common Pitfalls and How to Avoid Them

- Trying to do everything at once: focus wins over breadth.

- Ignoring data quality: invest early in master data and timestamps.

- Skipping user training: adoption is the multiplier for ROI.

- Over‑automating without guardrails: keep human oversight for high‑risk decisions.

- Neglecting governance: define who owns models, data, and outcomes.

Quick Implementation Checklist

- Select 1–2 pilot use cases with clear ROI.

- Assemble core data: sales, inventory, warehouse, fleet, supplier.

- Choose a prebuilt tool and run a 60–90 day pilot.

- Train the team and document new workflows.

- Measure results and prepare a scaling plan with governance.

Benefits of AI in Supply Chain

Implementing AI in the supply chain doesn’t just modernize operations — it transforms the entire way businesses plan, move, and deliver products. AI brings speed, precision, and intelligence to every stage, helping companies operate more efficiently while keeping customers happy.

A. Faster Operations

AI automates tasks that usually require hours of manual work.

From planning inventory to picking and packing orders, AI-powered systems complete these processes in minutes.

What this means for businesses:

- Quicker order processing

- Faster warehouse operations

- Shorter delivery timelines

- Improved overall productivity

AI helps teams focus on critical tasks while automation handles repetitive work.

B. Reduced Costs

Supply chains often suffer from hidden costs — excess inventory, inefficient routes, manual labor, and emergency shipments. AI helps cut these expenses significantly.

How AI reduces costs:

- Optimizes inventory so businesses don’t overstock or run out

- Suggests the most cost-efficient delivery routes

- Reduces the need for manual labor through automation

- Minimizes waste, delays, and errors

The result is a leaner, more profitable supply chain.

C. Higher Accuracy in Decision-Making

AI makes decisions based on real-time data, not outdated information or guesswork.

This leads to better planning and fewer mistakes.

AI improves accuracy by:

- Generating precise demand forecasts

- Predicting stock levels and replenishment needs

- Highlighting issues before they affect operations

- Providing insights instantly

Accurate decisions lead to more stable and reliable supply chain performance.

D. Better Customer Satisfaction

Customers today expect fast, predictable deliveries and consistent product availability. AI helps companies meet — and exceed — those expectations.

AI enhances customer experience by:

- Reducing delivery delays

- Preventing stockouts and shortages

- Improving order accuracy

- Ensuring consistent product availability

Happy customers lead to repeat purchases, higher ratings, and stronger brand loyalty.

E. Risk Reduction

Every supply chain faces risks — from supplier failures to natural disasters. AI acts like an early warning system, helping businesses prevent problems before they escalate.

AI reduces risk by:

- Predicting supply disruptions

- Detecting unusual patterns or fraud

- Identifying transportation delays

- Flagging equipment issues early

- Monitoring global events that might affect operations

With AI, companies become proactive instead of reactive, protecting themselves from costly disruptions.

Challenges of AI in Supply Chain

AI can transform supply chains, but real gains require navigating several common obstacles. Below I break down the four biggest challenges—what they look like in practice, why they matter, and concrete, actionable fixes you can apply today to keep projects moving and deliver measurable value quickly.

Data Fragmentation

What it looks like: Data lives in silos: spreadsheets on individual laptops, separate ERP modules, a legacy WMS, carrier portals, and supplier emails. Different teams use different versions of the same record, timestamps don’t match, and key fields are inconsistent. The result is noisy inputs for AI models and recommendations that users don’t trust.

Why it matters: AI is only as good as the data it consumes. Fragmented or inconsistent data produces unreliable forecasts, poor routing suggestions, and false alerts—undermining adoption and wasting budget.

How to solve it now

- Create a single source of truth: consolidate core tables (inventory, sales, orders, shipments) into a lightweight data layer or cloud data store. You don’t need a full ERP rip‑and‑replace to start—an integrated data hub for the pilot is enough.

- Standardize key fields: agree on SKU codes, location IDs, and timestamp formats. A short master data cleanup sprint (2–4 weeks) dramatically improves model performance.

- Automate data pipelines: use connectors or middleware to pull data regularly rather than relying on manual exports. Even daily automated extracts beat ad hoc spreadsheets.

- Log data lineage and quality metrics: track missing values, duplicate records, and latency so you can prioritize fixes and show improvement over time.

Quick KPI to watch Data completeness rate and time lag between transaction and availability in the model.

Skill Gaps

What it looks like: Teams may lack data science expertise, AI-savvy product owners, or operators who know how to interpret model outputs. Planners may distrust recommendations because they don’t understand the logic or how to act on exceptions.

Why it matters: Without the right skills, even excellent AI tools sit unused or are misapplied, producing little ROI and creating frustration.

How to solve it now

- Invest in role-based training: short, practical sessions for planners, warehouse leads, and logistics coordinators that focus on “how to use” rather than “how it works.” Teach them to read confidence scores, interpret alerts, and handle overrides.

- Hire or partner for data expertise: if you can’t hire a data scientist immediately, engage a vendor or consultant for an initial model setup and knowledge transfer.

- Use explainable AI tools: prefer solutions that show why a recommendation was made (key drivers, confidence levels). Explainability builds trust faster than black‑box outputs.

- Create AI champions: identify early adopters in operations who can evangelize wins and mentor peers.

Quick KPI to watch User adoption rate and percentage of AI recommendations accepted versus overridden.

High Initial Investment

What it looks like:Leaders assume AI requires massive budgets for custom models, new hardware, and long development cycles. This perception stalls pilots and pushes projects into “planning forever” mode.

Why it matters: Fear of cost prevents experimentation. Meanwhile competitors capture quick wins with lower risk approaches.

How to solve it now

- Start small and measurable: pick a single, high-impact use case—like improving forecast accuracy for top 100 SKUs or optimizing one delivery route—and run a 60–90 day pilot.

- Leverage SaaS and prebuilt models: many vendors offer subscription pricing and fast connectors that remove heavy upfront costs. Pay for outcomes, not infrastructure.

- Use phased investment: fund pilots from operational savings (e.g., reduced expedited freight) and reinvest realized savings into the next wave.

- Estimate realistic ROI: calculate expected savings from reduced stockouts, lower carrying costs, or fewer empty miles to justify incremental spend.

Quick KPI to watch Pilot ROI and payback period in months.

Change Resistance

What it looks like Operators and managers resist new workflows, fearing job loss, added complexity, or loss of control. They may ignore AI alerts or revert to manual processes when under pressure.

Why it matters Cultural resistance kills adoption. Even the best technology fails if people don’t use it.

How to solve it now

- Show quick, visible wins: choose pilots that produce tangible improvements within weeks—fewer stockouts, faster pick cycles, or reduced delivery times—and publicize those wins.

- Involve users early: co-design workflows with the people who will use the system. Their input reduces friction and increases ownership.

- Keep humans in the loop: start with AI as a decision support tool, not an autopilot. Allow easy overrides and clear escalation paths so staff feel safe experimenting.

- Communicate transparently: explain why AI is being introduced, what it will change, and how it will make daily work easier. Address job concerns honestly and highlight opportunities for upskilling.

Quick KPI to watch Rate of user engagement with AI tools and frequency of manual overrides.

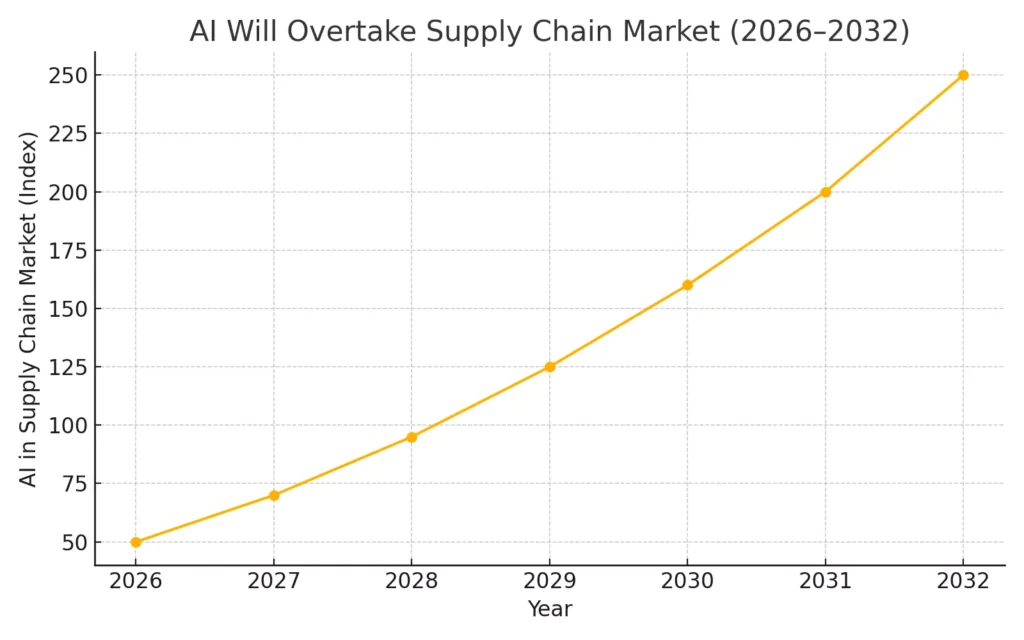

The Future of AI in Supply Chain

The future of supply chains is moving toward a fully intelligent, automated, and self-managing ecosystem. As AI becomes more advanced, supply chains will no longer rely heavily on manual planning or human intervention. Instead, they will operate like smart, interconnected systems that continuously learn, adapt, and improve.

What Tomorrow’s Supply Chains Will Look Like

- Fully autonomous

Supply chains will manage themselves end-to-end — from forecasting demand to fulfilling orders — with minimal human involvement. - Predictive and self-correcting

AI will identify potential issues before they occur and automatically adjust operations to avoid delays and disruptions. - Powered by AI agents

Intelligent AI assistants will analyze data, recommend actions, and even execute tasks across planning, logistics, and warehousing. - Data-driven at every stage

Decisions will no longer rely on intuition. Every movement — from production to delivery — will be guided by real-time data and AI insights. - Integrated with IoT, drones, and robotics

Smart devices, automated drones, autonomous vehicles, and warehouse robots will work together seamlessly to move products faster and more safely.

How AI Will Transform Daily Operations

Future AI systems will handle much of the operational workload on their own. For example, they will:

- Schedule deliveries automatically based on demand, traffic, and route efficiency.

- Reorder stock on time, ensuring inventory never runs too low or too high.

- Coordinate warehouses, from picking and packing to restocking shelves with robotics.

- Manage resources and workforce efficiently, predicting capacity needs in advance.

- Maintain smooth operations with near-zero manual input by continuously monitoring and correcting issues in real time.

In this future, supply chains will be faster, smarter, and almost entirely self-operating — giving businesses unprecedented efficiency, reliability, and resilience.

Conclusion

AI in supply chain is no longer optional – it’s becoming the backbone of modern business operations. Companies that adopt AI early gain faster delivery times, reduced costs, smarter planning, and stronger resilience. Whether you’re running a small business or a global enterprise, implementing AI step by step can transform your entire supply chain within months.

By embracing predictive analytics, automation, robotics, and real-time intelligence, businesses can boost efficiency faster than ever before and stay competitive in a rapidly changing world.