AI in industrial automation is transforming how factories operate by making processes faster, more accurate, and more cost-efficient. It replaces slow manual workflows with intelligent systems that can make decisions, predict issues, optimize machines, and improve output without constant human involvement. In simple terms, AI helps industries run smarter—reducing errors, increasing efficiency, and delivering consistent, high-quality results.

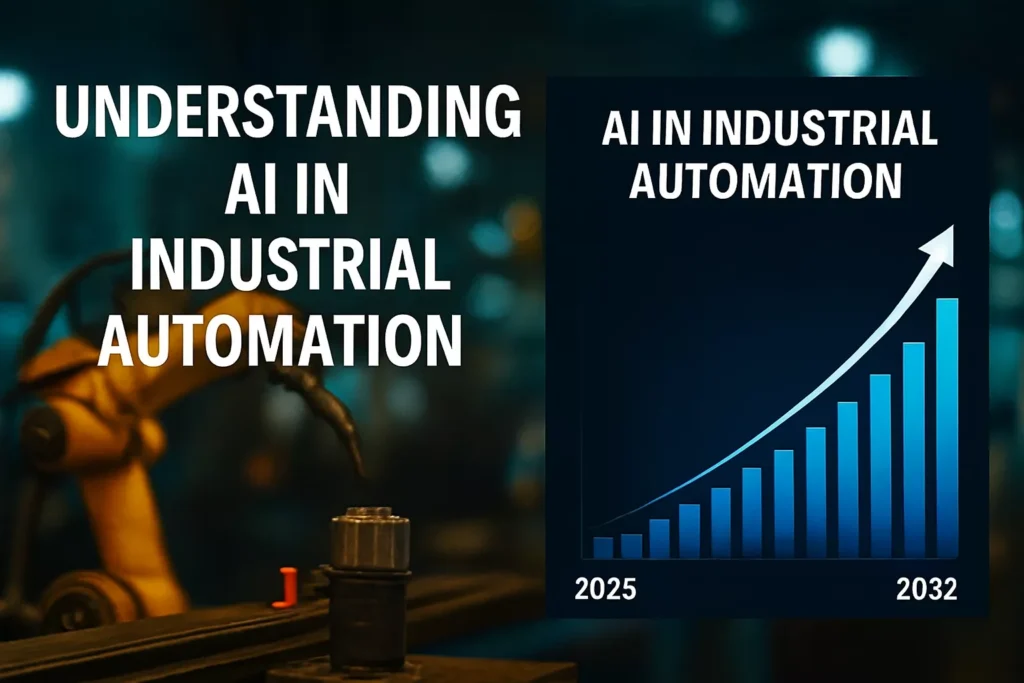

Understanding AI in Industrial Automation

Industrial automation has existed for decades, but traditional systems rely on fixed rules, pre-programmed responses, and limited insights. Artificial Intelligence changes this entirely.

AI-powered automation introduces intelligence into machines, enabling them to:

- Learn from data

- Make predictions

- Detect patterns

- Adjust operations in real time

- Identify inefficiencies instantly

- Understand complex scenarios

- Reduce human error

This shift takes industries from “automated but rigid” to “automated and self-improving.”

Why AI Matters in Modern Manufacturing

Modern industries face tighter deadlines, rising labor costs, global competition, and growing quality demands. AI automation solves these challenges naturally because it can:

- Monitor thousands of variables at once

- Predict failures before they occur

- Reduce wastage and downtime

- Optimize production around the clock

- Replace repetitive human tasks

As a result, manufacturers achieve better output with fewer disruptions and higher accuracy.

Key Ways AI Boosts Efficiency and Accuracy

1. Predictive Maintenance: Fix Problems Before They Happen

In traditional factories, equipment is usually repaired only after it breaks—leading to expensive downtime and production slowdowns. AI completely transforms this approach with predictive maintenance.

Using sensors, machine learning models, and real-time data, AI continually monitors machine health. It identifies early warning signs such as abnormal vibration, temperature changes, or unusual power consumption—signals that often go unnoticed by human operators.

This proactive insight directly impacts productivity:

- Downtime drops by up to 40% because issues are fixed before breakdowns occur.

- Maintenance costs decrease since repairs are planned, not rushed in emergencies.

- Machines last longer, thanks to timely interventions that prevent severe damage.

Instead of relying on guesswork or scheduled checkups, AI provides precise predictions—ensuring equipment stays reliable and efficient.

2. Quality Control Automation: Achieving Perfect, Consistent Production

Quality control is one of the toughest challenges in manufacturing. Humans naturally get tired, overlook tiny defects, and struggle with repetitive inspection tasks. AI-powered vision systems eliminate these limitations entirely.

These systems use high-resolution cameras and deep learning to inspect products with microscopic accuracy. They can detect:

- Minute surface defects

- Subtle size or shape variations

- Internal or structural inconsistencies

- Misalignment and assembly errors

Unlike human inspectors who may miss small flaws after long shifts, AI maintains 100% accuracy, 24/7.

This results in:

- Higher product quality and fewer defective items

- Reduced rework, saving time and materials

- Consistent standards across every batch

- Lower customer complaints, improving brand trust

AI ensures every product meets the highest level of precision—every time.

3. Intelligent Supply Chain Optimization: Faster, Smarter, More Predictive

A supply chain involves hundreds of moving parts—materials, inventory, shipments, and demand timelines. AI simplifies this complexity by transforming the entire system into a predictive, data-driven network.

AI improves supply chain performance by:

- Forecasting demand with high accuracy

- Monitoring inventory levels in real time

- Optimizing warehouse layouts for faster movement

- Recommending ideal transport routes

- Preventing material shortages before they disrupt production

Instead of reacting to problems as they arise, businesses can stay ahead by making decisions based on AI-driven insights. The result is a smoother, more efficient supply chain that reduces delays and keeps production running seamlessly.

4. Robotics and Autonomous Systems: Smarter Machines That Learn and Adapt

AI-powered robots are no longer limited to fixed routines. They now possess the intelligence to learn, adapt, and collaborate—creating safer and more efficient factories.

Advanced robots can:

- Optimize their movements for speed and precision

- Learn new tasks without reprogramming

- Avoid obstacles and prevent collisions

- Work alongside human operators safely

- Handle fragile or complex materials with care

These collaborative robots—often called cobots—are designed to assist humans by taking over:

- Repetitive, monotonous tasks

- Heavy lifting and physically demanding activities

- Hazardous or risky operations

This not only boosts productivity but also significantly improves worker safety, reducing injuries and fatigue while increasing overall output.

5. Workflow Automation and Smart Scheduling: Streamlining Operations Automatically

AI removes inefficiencies across the production floor by analyzing patterns and restructuring workflows. It evaluates historical data, ongoing trends, and machine performance to generate the most optimized schedules.

AI enhances operations by refining:

- How tasks are distributed

- Which machines are assigned to which jobs

- Worker scheduling and shift planning

- Resource allocation across departments

It also identifies hidden bottlenecks—like slow-moving processes or underutilized equipment—and suggests improvements automatically. This leads to smoother, uninterrupted production and a significant boost in operational efficiency.

6. Energy Efficiency Optimization: Lower Costs, Higher Sustainability

Energy consumption is a major expense in industrial environments. AI helps companies control and reduce their energy usage without sacrificing performance.

AI systems monitor energy patterns and optimize consumption by:

- Tracking real-time power usage

- Regulating high-energy machines intelligently

- Predicting peak-load periods to avoid excess charges

- Controlling heating, cooling, and ventilation automatically

The outcome is lower energy bills and a reduced environmental footprint—making AI a powerful tool for sustainability initiatives.

7. Real-Time Monitoring and Error Detection: Instant Awareness, Zero Delays

AI doesn’t just automate tasks—it functions as the factory’s eyes and ears. Through thousands of interconnected sensors, AI continuously observes the entire production environment.

It can detect:

- Unusual machine vibrations

- Sudden temperature spikes

- Pressure inconsistencies

- Safety hazards

- Operational inefficiencies

- Minor irregularities that could escalate quickly

These systems generate instant alerts, allowing teams to address issues immediately—often within seconds. This prevents small problems from turning into expensive breakdowns or quality failures.

With AI monitoring everything in real time, factories achieve unmatched reliability and stability.

Industries Benefiting Most from AI Automation

A. Manufacturing: The Heart of the AI Revolution

Manufacturing is one of the biggest beneficiaries of AI automation. Whether it’s automotive, electronics, textiles, or heavy machinery, AI enhances every layer of the production process.

AI boosts manufacturing through:

- High-precision assembly line work that reduces human error

- Smarter robotic systems that adapt to tasks and collaborate with workers

- Fully automated packaging lines that increase speed and consistency

- Optimized workforce productivity through real-time insights

- Advanced fault detection that catches defects long before products reach customers

With AI-driven smart factories, manufacturers now achieve greater consistency, reduced downtime, and higher output. What used to require hundreds of workers can now be handled by intelligent systems operating 24/7.

B. Oil & Gas: Enhancing Safety and Operational Efficiency

The oil and gas sector faces constant pressure to maintain safety while maximizing production. AI offers real-time analysis that helps companies monitor and manage high-risk operations with incredible accuracy.

AI strengthens this industry by predicting:

- Pipeline leaks before they escalate into accidents

- Equipment faults that could cause shutdowns

- Hazardous conditions that endanger workers

- Production variations that affect supply and profitability

By forecasting problems early, AI reduces environmental risks, improves worker safety, and makes energy operations more efficient and reliable.

C. Automotive: Driving Precision and Speed

The automotive industry has embraced AI faster than almost any other sector. Modern car production relies heavily on intelligent automation to maintain the highest level of accuracy.

AI accelerates automotive manufacturing through:

- Robotic welding and painting, delivering flawless finishes

- Autonomous assembly lines capable of adjusting to different car models

- Instant quality checks on every component

- Smart logistics that ensure materials arrive exactly when needed

These advancements lead to faster production cycles, higher precision, and reduced defects, allowing automakers to keep up with global demand while minimizing costs.

D. Pharmaceuticals: Ensuring Quality Where It Matters Most

In the pharmaceutical industry, even the smallest mistake can have serious consequences. AI helps maintain strict quality standards and supports the production of safe, effective medications.

AI ensures:

- Perfect consistency across batches, reducing variation

- Accurate dosage filling, which is critical for patient safety

- Sterile, contamination-free environments monitored by intelligent systems

- Precise, error-free packaging

Pharma companies rely on AI to prevent human errors, streamline processes, and accelerate production—especially important in vaccine and drug manufacturing.

E. Food & Beverage: Delivering Safety and Freshness

Consumers expect safe, fresh, high-quality food—and AI helps companies meet those expectations efficiently.

AI enhances food and beverage operations by improving:

- Hygiene compliance, detecting contamination risks early

- Shelf-life predictions, reducing waste and overproduction

- Automated quality inspections, ensuring products meet safety standards

- Packaging efficiency, speeding up delivery to stores and customers

With AI monitoring every step, food companies achieve safer processing, faster output, and more consistent product quality.

F. Electronics: Precision at a Microscopic Level

The electronics industry demands unmatched accuracy, especially when manufacturing delicate components like microchips and sensors. AI brings the precision required to handle these sensitive tasks.

AI-powered automation supports:

- Micro-level inspections that detect flaws invisible to the human eye

- Advanced chip manufacturing, ensuring flawless circuits

- Thermal and environmental control, protecting components during production

- High-precision assembly, essential for devices like smartphones, laptops, and medical electronics

As electronic devices become smaller and more complex, AI plays a crucial role in ensuring reliability and performance.

AI Technologies Driving Industrial Automation

Machine Learning

Machine learning (ML) turns raw operational data into continuous improvement. By training models on sensor streams, production logs, and historical failures, ML systems predict equipment breakdowns, spot anomalous patterns, and optimize throughput without explicit reprogramming. Typical industrial applications include:

- Predictive maintenance that schedules repairs before failures occur.

- Pattern recognition for process drift and anomaly detection.

- Automated quality checks that learn what “good” looks like from examples.

- Demand forecasting that aligns production with market signals. ML is a cornerstone of Industry 4.0, enabling factories to move from reactive to proactive operations.

Computer Vision

Computer vision gives machines the ability to “see” and interpret visual information at scale. Modern vision systems combine high‑resolution cameras with deep learning to inspect parts, verify assemblies, and read labels faster than human operators. Common use cases:

- Surface defect detection that finds scratches, dents, or discoloration.

- Assembly verification to ensure every component is present and correctly oriented.

- Barcode and label reading even on curved or damaged surfaces.

- Package inspection for correct sealing and labeling. These systems reduce human error, speed up inspection lines, and enable 100% inspection coverage where sampling once sufficed.

Natural Language Processing (NLP)

NLP bridges human language and machine control, making interactions intuitive for frontline workers. Instead of navigating complex HMIs, operators can use voice or text to query systems, log incidents, or receive step‑by‑step instructions. Practical deployments include:

- Voice instructions on factory floors for hands‑free guidance.

- Automated reporting that converts spoken notes into structured incident logs.

- AI assistants for operators that surface troubleshooting steps and SOPs. NLP reduces training time and helps preserve institutional knowledge in searchable form.

Edge AI

Edge AI runs models locally on devices at the factory edge rather than relying on cloud roundtrips. The benefits are clear: faster processing, lower latency, improved security, and greater reliability during network outages. Edge deployments are ideal for time‑sensitive tasks like real‑time control loops, safety monitoring, and on‑device vision inference. Moving compute to the edge also reduces bandwidth costs and keeps sensitive data on‑premises.

Digital Twins

A digital twin is a live virtual replica of a machine, line, or entire plant. By simulating performance, stress levels, failure points, and optimization strategies, teams can test changes virtually before applying them on the shop floor. Digital twins accelerate design iterations, validate control strategies, and quantify ROI for process changes—letting companies experiment safely and cheaply.

Risks, Trade‑offs, and Practical Steps

Key trade‑offs include data quality needs, model drift, integration complexity, and cybersecurity exposure. To manage these:

- Start small with pilot projects and measurable KPIs.

- Invest in data hygiene and labeling to improve model accuracy.

- Use hybrid architectures (edge + cloud) for resilience.

- Plan for lifecycle management to retrain models and monitor drift. Adopting AI in industrial settings is a strategic journey—expect measurable gains but plan for governance and change management

Benefits of AI in Industrial Automation

AI is transforming industrial operations in ways that were once impossible. By bringing intelligence, speed, and precision to everyday processes, AI helps factories run smoother, smarter, and more profitably. Here’s a closer look at the major benefits.

i. Higher Efficiency: Getting More Done in Less Time

AI streamlines every stage of production—from machine operation to scheduling—helping industries achieve peak performance. With intelligent automation in place, factories can:

- Produce more output in shorter cycles

- Minimize idle time caused by delays or mismanagement

- Keep machines operating at their most efficient levels

- Reduce manual intervention and repetitive tasks

The result is a faster, more productive workflow that keeps businesses ahead of the competition.

ii. Improved Accuracy: Consistency You Can Trust

Human errors are inevitable, especially in repetitive or high-precision tasks. AI removes this barrier by ensuring consistent, accurate results every single time.

AI delivers:

- Superior product quality across all batches

- Precision manufacturing without deviations

- Fewer mistakes, thanks to real-time monitoring and automated controls

This level of accuracy not only boosts customer satisfaction but also strengthens brand reliability.

iii. Lower Operational Costs: Saving Money Automatically

AI helps factories cut costs in multiple areas by:

- Reducing material wastage

- Preventing unplanned downtime

- Lowering defect rates

- Optimizing energy consumption

- Minimizing the need for manual quality checks

With AI, companies spend less on repairs, labor, and production errors—leading to higher profit margins.

iv. Safer Work Environments: Protecting People First

Industrial sites often involve heavy machinery, hazardous materials, and complex processes. AI enhances workplace safety by:

- Taking over dangerous, repetitive, or physically demanding tasks

- Detecting safety risks before they escalate

- Monitoring environmental conditions such as temperature, pressure, or gas levels

By reducing human exposure to risk, AI helps employees work in safer, stress-free environments.

v. Faster Decision-Making: Insight at the Speed of Data

With AI analyzing real-time information and spotting trends instantly, decision-makers get the insights they need exactly when they need them. Leaders can make:

- Quick adjustments to production

- Informed strategy decisions

- Accurate forecasts

- Immediate responses to disruptions

This agility allows businesses to stay competitive and adapt quickly to market changes.

vi. Greater Scalability: Grow Without Limits

Scaling up production usually requires more manpower and more complex planning. AI changes that. Intelligent automation allows factories to:

- Increase output without expanding the workforce

- Maintain consistent quality at higher volumes

- Add new production lines with minimal downtime

AI makes growth smoother and more manageable—perfect for industries looking to expand rapidly.

Challenges of AI Adoption in Industrial Automation

AI brings powerful capabilities to factories, but implementing it at scale introduces real obstacles that organizations must plan for and manage. Below are the primary challenges, why they matter, and practical steps to address each one.

High Initial Investment

What it is: Deploying AI often requires new hardware, sensors, robotics, software licenses, and integration work, which can create a significant upfront cost.

Why it matters: Large capital outlays can slow adoption, especially for small and medium manufacturers with tight budgets.

How to manage it: Start with targeted pilots that demonstrate clear ROI, pursue phased rollouts, and explore financing, leasing, or vendor-as-a-service models to spread costs.

Skill Gaps

What it is: Successful AI projects need people who understand data science, machine learning operations, industrial controls, and change management.

Why it matters: Without the right skills, projects stall, models degrade, and operators resist new workflows.

How to manage it: Invest in upskilling and cross‑functional teams, partner with universities or vendors for training, and hire or contract specialists for critical phases.

Data Quality Issues

What it is: AI models require clean, well‑labeled, and representative data; noisy, incomplete, or biased data undermines performance.

Why it matters: Poor data leads to inaccurate predictions, false alarms, and lost trust in AI systems.

How to manage it: Implement data governance, standardize sensor calibration and logging, automate labeling where possible, and run small experiments to validate data pipelines before scaling.

Integration Complexity

What it is: Many factories run legacy equipment and disparate control systems that were not designed for modern AI workflows.

Why it matters: Integrating AI with older PLCs, SCADA systems, and MES can be time‑consuming and technically challenging.

How to manage it: Use middleware and standardized APIs, prioritize retrofit-friendly solutions, map integration points early, and plan for incremental upgrades rather than wholesale replacement.

Cybersecurity Risks

What it is: Connecting machines, sensors, and AI platforms increases the attack surface and introduces new vectors for data theft or operational disruption.

Why it matters: A successful cyberattack can halt production, damage equipment, or expose sensitive IP and customer data.

How to manage it: Apply defense‑in‑depth strategies, segment networks, enforce strong access controls and encryption, and include security assessments in every deployment phase.

The Future of AI in Industrial Automation

AI is rapidly evolving, and its impact on industrial automation will only grow stronger in the coming years. Factories are moving toward intelligent, self-optimizing systems that can think, adapt, and coordinate without constant human intervention. Here’s what the future is shaping up to look like:

1. Fully Autonomous Factories

Next-generation factories will operate with minimal supervision as AI systems make independent decisions about production, maintenance, and resource allocation. Machines will diagnose issues, adjust workflows, and even repair themselves—creating a seamless, uninterrupted production environment.

2. AI-Driven Workforce Assistance

AI will act as a real-time advisor for technicians, engineers, and machine operators. Through smart glasses, voice assistants, or digital dashboards, AI will provide instant guidance, troubleshooting steps, safety alerts, and performance insights—empowering workers to operate more efficiently.

3. Hyper-Personalized Production

Demand fluctuations will no longer disrupt operations. AI will enable factories to automatically adjust production lines, customize output for specific orders, and maintain consistency even with rapid changes. This means personalized products at the speed and scale of mass manufacturing.

4. Multi-Agent AI Systems

Instead of one central AI, multiple specialized AI agents will collaborate to manage entire industrial ecosystems. One agent may monitor machine health, another may optimize energy use, while another coordinates supply chains. Together, they will create a fully synchronized, intelligent factory.

5. Sustainable, Low-Energy Operations

Sustainability will be at the core of future automation. AI will constantly analyze energy consumption and reduce waste by managing power-heavy systems, optimizing climate control, and ensuring machines run only when needed. This leads to greener operations and significant cost savings.

Conclusion

AI in industrial automation is revolutionizing how factories operate – making them smarter, faster, safer, and significantly more accurate. From predictive maintenance and intelligent robotics to energy management and real-time monitoring, AI enhances every layer of industrial processes.

Companies that adopt AI early will lead the next wave of global manufacturing, achieving higher productivity, lower costs, and superior product quality. AI is not just a technological upgrade – it’s the foundation of the future industrial world.

FAQs

1. How is AI transforming traditional industrial automation?

AI brings intelligence to automation systems by enabling real-time decision-making, predictive maintenance, error detection, and adaptive workflows. Instead of simply following programmed commands, machines can now learn, optimize, and operate autonomously.

2. What are the biggest benefits of using AI in manufacturing?

The top benefits include reduced downtime, improved product quality, faster production cycles, lower operational costs, enhanced worker safety, and higher overall efficiency through smarter, data-driven automation.

3. Can AI reduce human labor in industries?

AI doesn’t replace workers—it shifts them to safer, more skilled roles. AI handles repetitive, dangerous, and precision-heavy tasks, while humans focus on supervision, creativity, system management, and complex decision-making.

4. What industries are adopting AI automation the fastest?

Manufacturing, automotive, electronics, oil & gas, pharmaceuticals, food & beverage, and logistics are leading AI adoption due to high demand for accuracy, safety, and fast production.

5. How costly is implementing AI in industrial automation?

Initial investment can be high due to sensors, software, robotics, and integration. However, companies typically see a fast ROI through reduced downtime, fewer defects, energy savings, and improved productivity.